Should they be really stuck on there you can pry them open carefully with a well fitting screwdriver in the slot, taking care not to damage them. These can be twisted off using fingers, they are just held in place by friction. Smart of you to ask questions! Ring 1 and 2 are both dust covers.

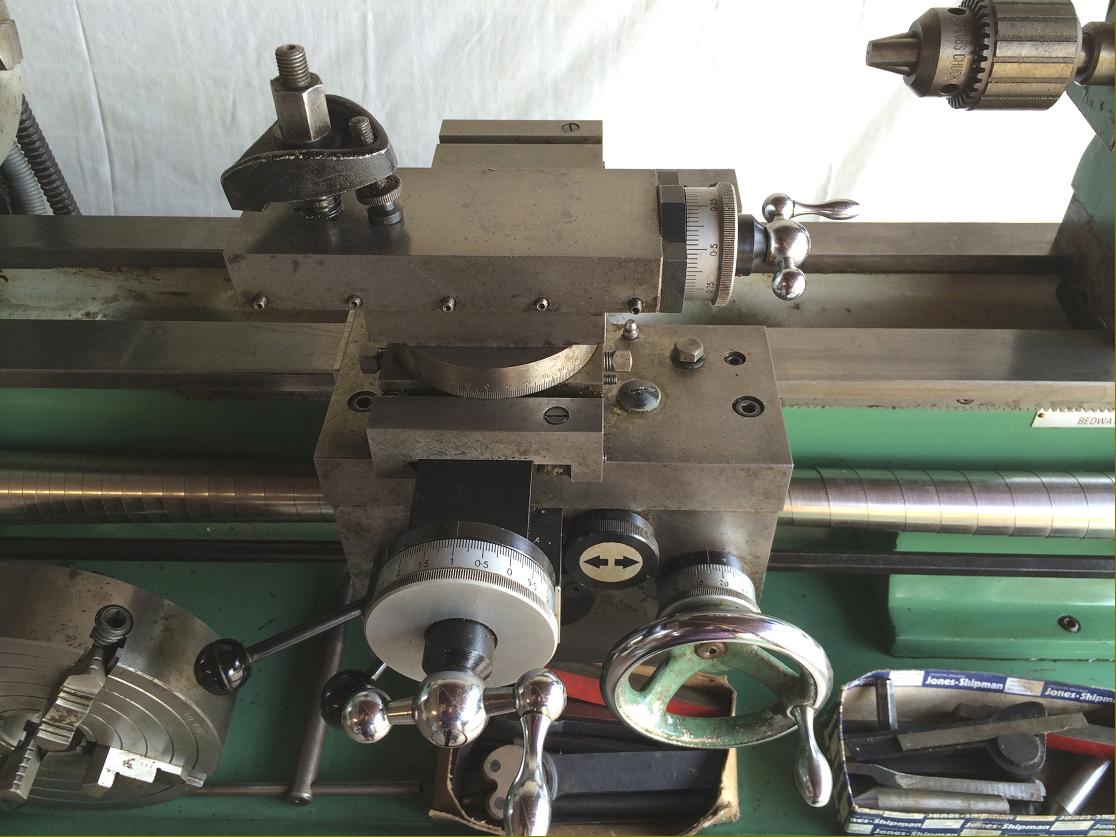

001 inch.Burgos, although I'm not a native speaker, I think your English is nothing to apologize for. If a 5/16 feed screw had a vee thread, it would probably be 5/16-20 and the index would have 50 divisions, each equal to. On an American lathe like the Hardinge Cataract, the screw is 5/16-10 square thread and the index would also have 100 divisions, each equal to. It would be normal for the screw on a German lathe to be M8x1 and the index to have 100 divisions, each equal to. If it were mine, I would fit your slide rest with a new feed screw and nut with either 1 mm lead or 20 TPI pitch and make dials with 100 or 50 divisions. It was a wonderful thing when I replaced that "learning lathe" with a real one after my circumstances allowed. My first metal lathe, in 1954, had 24 TPI feed screws with no dials, so I know about this. Running a lathe slide rest without an index dial on the feed screw is a very unpleasant task. But it looks like there are knurled parts with locking screws in the place where index dials should be. In your picture ( ), I can see no division marks where the index dials should be. If your slide rest has an index dial, you can judge from the number of divisions whether the 18 TPI feed screw is a replacement. Is there an index dial with graduations on that screw? There is no way to make 18 TPI work with an index dial. Miss E, I am worried by your report that the slide rest feed screw is 5/16-18 UNC. For light work you can loosen the bearings and easily go to 1800- 2000rpm Spindle speeds for average work - about 1000-1200rpm. It really takes a lot of abuse to destroy this type of bearing. Check the bearings and continue the process until the bearings turn true. I use an electric hand drill with a shaft and universal chucked in a collet to drive the bearing concentric. DO NOT USE the drive belt to turn the lathe as you may "egg" the bearings. Start turning the lathe and slowly adjusting the bearings tighter. Put the oil and compound slurry in the bearings. Be sure to get the timesavers that is compatible with the bearing materials. Get some "timesavers" lapping compound (don't use regular lapping compound) and mix with spindle oil. If they still don't turn properly I would try relapping the bearings before you do anything else. They may look scored but function very well. Before I would do any grinding or anything else to those bearings I would first clean them, oil properly and adjust then try them out. The "thrust bearing" is the bearing adjustment. The bearings ride on a film of oil between the metals in the cone. The bearings appear to be the typical dissimilar metal cone bearings as found in watchmaker lathes. From your pics, the construction and size is very similar. I don't have a Lorch but I have a number of 7" vintage US precision bench lathes. I am in the process of repainting, as you can see from the pictures, and there are a lot of little jobs along the way, but I am hoping I end up with a machine with a reasonable level of precision when its all done. I wonder how I can hook this up to work up to 1200 rpm, maybe, and what a good range of speeds may be.Īlso wonder If anyone knows what model lorch this might be?

Lorch lathe instruction manual full#

I wonder if anyone has done this to a lathe like this? the motor I looked at did 2500 RPM full speed, and I would like to keep the flat belt drive. I am thinking to fit a 500 w DC motor (36v) with an electronic speed control.

It also needs new graduated screws, has anyone any experiece with either of these jobs? they are brass, so i guess the best way will just be to make new ones. Ill try to fit a sleeve back inside, eventually. The spindle has been bored out to maximum size unfortunately, where it once held 12.5mm lorch collets. I wonder how fast a plain bearing spindle should run? my little ww watchmakers lathe (my trade) runs ok at 1500 rpm, for short bursts, with a very similar bearing system. I have planned a manganese bronze replacement, and at the moment I'm having the spindle journal ground parallell again. The spindle bearings are a bit of a mess, one of them is a recycled plumbing fitting. You can check out my restoration progress at an you can see it is coming along niceley. it has a 800mm bed, is 100mm centre height, and is in fairly sweet condition. I have bought a little lorch lathe recently, and have been spending some time and money setting it up and restoring it. I am posting this here, I did post it in the european toolroom lathe section, but I didnt get many replies, so In view of how old it may be, I will post it here again.

0 kommentar(er)

0 kommentar(er)